|

Before you change the parameter settings for MDI PWE = 1 mode, appears Alarm 100 push CAN + RST and you're ready for setting parameters.

Cable data.

For 9 pin serial on PC RJ45 DB9 For 25 pin serial on CNC RJ45 DB 25

5---------------------------------------------------------7

8---------------------------------------------------------4

2---------------------------------------------------------2

7---------------------------------------------------------5

3---------------------------------------------------------3

To DB 25 Pin 6,8,20 Jumper

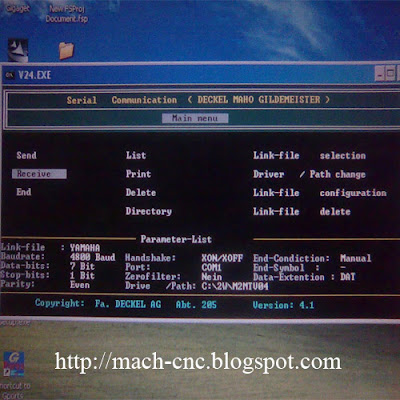

Setting to PC

Baudrate = 4800 (Must match CNC setting).

Stop bits = 2

Data bit = 7

Parity = Even

Control code = Xon/Xoff

Setting CNC

Fanuc O series

CNC Setting Data

TV ON = 0

ISO = 1

I/O =0

Parameter 0002 = 000000001

0552 = 10 (Baudrate 4800).

Fanuc 6 series

CNC Setting Data

TV CHECK = 0

PUNCH CODE = 1

INPUT UNIT = 0

INPUT DEVICE 1 = 1

INPUT DEVICE 2 = 1

Parameters 306 = *00010*0

311 = 00001001

340 = 2

341 =1

* = Leave this bit set to what is currently

Fanuc 3 series

CNC Setting Data

TV ON = 0

ISO = 1

I/O= 0

Parameters 005 = 00000001

068 = 4800

Fanuc 10/11/12 Series

CNC Setting Data

TV CHECK = 0

PUNCH CODE = 0

INPUT DEVICE =1

INPUT DEVICE = 1

Parameter 5001 = 1

5110 = 1

5111 = 2

5112 = 10

Fanuc 16 / 18 Series

CNC Setting Data

TV CHECK = 0

PUNCH CODE = 1

I/O CHANNEL = 0 (0-3: CHANNEL NO)

TAPE FORMAT = 0

Parameters

0000 = 00000*10

0020 = 0

0100 = 00000000

0101 = 10000001

0102 = 0

0103 = 10

* = Leave this bit set to what is currently.

You interested my other articles