Almost every manufacturing company has CNC equipment there are many

types and brands like Makino cnc machining centers, Toyosk, Okuma &

Howa and many others. All brands of course have many advantages and

disadvantages depending on what products will be in the process. Example

for milling process I prefer okuma & howa because they are special

in milling processes and machines are very robust and proven

reliability. The main function of the CNC machining center is that it

reduces manual labor and also save time. Because the machine is set by

the computer, the various calculations involved in the job taken care of

as well. Processes that can be done include CNC

boring milling, drilling and tapping. CNC machining center to do all

the work themselves, with perfect precision. To run a CNC machine

programmers need to be in need, because the movement of the machine had

been instructed via the computer. Thus not everyone can run a CNC

machine needs to learn, a lot of places to study for cnc programming

even in school - the school have been taught but the basic program. To

further explore the need to have special training. In the CNC machining

centers have 3 movement you should know that the first is the Circular

Motion is a motion in a circle this is usually to make a seal holes in

the second cylinder Straight Line Motion allows the machine to move in a

straight line is usually to move the process of milling and then the

third This movement also called movement position because this movement

without cutting, bias to avoid crashing into material tool when the tool

change (ATC), so need to move position.

You maybe reading articles CNC machine. That's it again next time

Parameter Configurations For Fanuc - Backup Data

|

Before you change the parameter settings for MDI PWE = 1 mode, appears Alarm 100 push CAN + RST and you're ready for setting parameters.

Cable data.

For 9 pin serial on PC RJ45 DB9 For 25 pin serial on CNC RJ45 DB 25

5---------------------------------------------------------7

8---------------------------------------------------------4

2---------------------------------------------------------2

7---------------------------------------------------------5

3---------------------------------------------------------3

To DB 25 Pin 6,8,20 Jumper

Setting to PC

Baudrate = 4800 (Must match CNC setting).

Stop bits = 2

Data bit = 7

Parity = Even

Control code = Xon/Xoff

Setting CNC

Fanuc O series

CNC Setting Data

TV ON = 0

ISO = 1

I/O =0

Parameter 0002 = 000000001

0552 = 10 (Baudrate 4800).

Fanuc 6 series

CNC Setting Data

TV CHECK = 0

PUNCH CODE = 1

INPUT UNIT = 0

INPUT DEVICE 1 = 1

INPUT DEVICE 2 = 1

Parameters 306 = *00010*0

311 = 00001001

340 = 2

341 =1

* = Leave this bit set to what is currently

Fanuc 3 series

CNC Setting Data

TV ON = 0

ISO = 1

I/O= 0

Parameters 005 = 00000001

068 = 4800

Fanuc 10/11/12 Series

CNC Setting Data

TV CHECK = 0

PUNCH CODE = 0

INPUT DEVICE =1

INPUT DEVICE = 1

Parameter 5001 = 1

5110 = 1

5111 = 2

5112 = 10

Fanuc 16 / 18 Series

CNC Setting Data

TV CHECK = 0

PUNCH CODE = 1

I/O CHANNEL = 0 (0-3: CHANNEL NO)

TAPE FORMAT = 0

Parameters

0000 = 00000*10

0020 = 0

0100 = 00000000

0101 = 10000001

0102 = 0

0103 = 10

* = Leave this bit set to what is currently.

You interested my other articles

Components CNC Vertical Milling Machine

Milling

machine is divided there are 2 types of Vertical and Horizontal

orientation of the term refers to the cutting spindle. That the mean

vertical position of the machine spindle and cutting direction vertical

and horizontal machinery is horizontal spindle position (horizontal

cutting direction). Here I will discuss CNC Vertical milling machine. I

will discuss the critical components on CNC Vertical Milling Machine.

- Table machine. Vertical milling machine can move with 2 axis X and axis Y. for each axis is equipped with a servo motor which in control through the amplifier with a command from the computer with a precision movement. Also equipped with a ballscrew, bearings and linear guide. Usually use oil for lubrication, this is very important because to maintain the smoothness of movement and ballscrew will be durable. This table you can move it manually by turning the pulse generator.

- Spindle machine. This section is a spindle house, this is what set the spindle rotation axis Z. cutting moves this spindle motor is also in motion by using a timing belt as the transmission.

- Control Panel. Control Panel contains a collection of many buttons are in front of the machine that serves to give commands such as rotating spindle, to change parameters, and other programs.

- Monitor. The monitor will display the position coordinates, position the machine, parameters, diagnostics and others.

- Magazine tool. Magazine tool is to place the standby tool to be used in a single machining operation. Because in one program usually use some kind of tool. Tool exchange is performed automatically called ATC (Automatic Tool Change).

- Coolant. Coolant used for cooling at the cutting progresses, each machine is equipped with the system.

That's the critical components on CNC Vertical Milling Machine.

Are you going to read another article

- Table machine. Vertical milling machine can move with 2 axis X and axis Y. for each axis is equipped with a servo motor which in control through the amplifier with a command from the computer with a precision movement. Also equipped with a ballscrew, bearings and linear guide. Usually use oil for lubrication, this is very important because to maintain the smoothness of movement and ballscrew will be durable. This table you can move it manually by turning the pulse generator.

- Spindle machine. This section is a spindle house, this is what set the spindle rotation axis Z. cutting moves this spindle motor is also in motion by using a timing belt as the transmission.

- Control Panel. Control Panel contains a collection of many buttons are in front of the machine that serves to give commands such as rotating spindle, to change parameters, and other programs.

- Monitor. The monitor will display the position coordinates, position the machine, parameters, diagnostics and others.

- Magazine tool. Magazine tool is to place the standby tool to be used in a single machining operation. Because in one program usually use some kind of tool. Tool exchange is performed automatically called ATC (Automatic Tool Change).

- Coolant. Coolant used for cooling at the cutting progresses, each machine is equipped with the system.

That's the critical components on CNC Vertical Milling Machine.

Are you going to read another article

Subscribe to:

Posts (Atom)

-

Below are fanuc servo drive alarm codes for the spindle amplifier on CNC Machining: Alarm 01 (AL-01) Motor Overheat Causes Damaged mot...

-

Do you want to add / edit the ladder diagram on your Robodrill CNC Machine? you can add the engine accessories, such as conveyor coolant or...

-

How to backup fanuc parameters, PMC Parameter , Program, Tool Offset, and Macro Variable CNC Machine Fanuc follow the steps below: Mode...

-

The first step used to prepare FANUC memory card, then input into the slot near the screen, Operation : Turn the power on by simultaneously ...

-

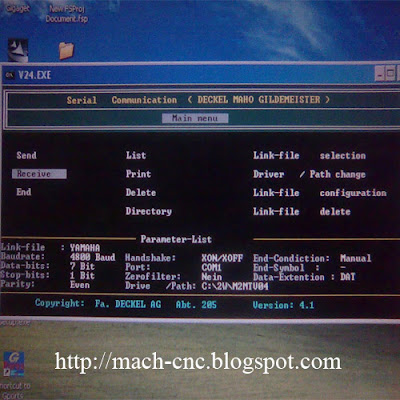

The first parameter settings on the PC: Baud rate = 4800 Data bits = 7 bits Stop bits = 1 bit Parity = Even Handshake = XON / XOF...